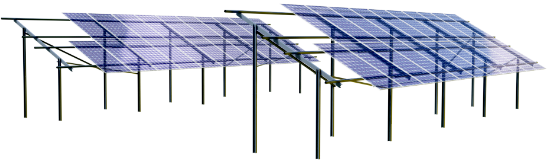

SOLAR PANEL SUPPORT STRUCTURE SYSTEMS FOR SOLAR PARKS

As solar panels are becoming more and more popular around the world, more and more businesses are looking to take advantage of them.

The metal structures offered by us are ideal for photovoltaic panels (solar panels), and because they are made of light steel profiles designed and manufactured with high precision, the assembly becomes easy and fast.

All the profiles used in our solar panel structure systems are made of S350-GD galvanized structural steel (from Zn 450 up to ZnMg 310 gr/m²), corrosion resistant, have a very low weight and have a high strength. Because of this, the structure will last much longer than the solar panels mounted on it.

Our team of professionals will design-engineer the ideal and cost-effective solar panel support structures for the most complex projects of solar fields, based on the configuration provided by the Customers.

GROUND ANCHORAGE SYSTEMS FOR PHOTOVOLTAIC STRUCTURE

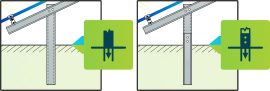

◼ Anchoring by hammering into the ground

Can be installed using the classic technology of piles (in this case profiles) hammered into the ground .

• profile type: steel „C” profile

• profile length: individually determined based on the topographic plan

• pile depth: minimum 1500 mm depending on the quality of the soil

◼ Anchoring by embedding in concrete

Can be installed by embedding in concrete according to the specified parameters.

• profile type: steel „C” profile

• profile length: individually determined based on the topographic plan

• concrete block depth: 800 – 1000 mm (depending on the frost depth of the area)

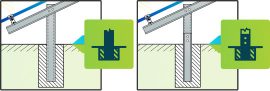

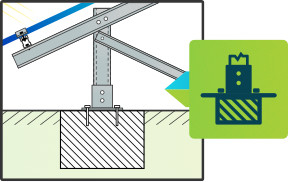

◼ Mechanical anchorage to foundation

The system can be fixed to an existing concrete foundation according to the specified parameters.

The system can be fixed to an existing concrete foundation according to the specified parameters.

• profile type: steel „C” profile

• profile length: individually determined based on the installation plans

• fixing method: 2 pcs. of M12 chemically anchored threaded rods/leg in the quality chosen according to the condition of the concrete base

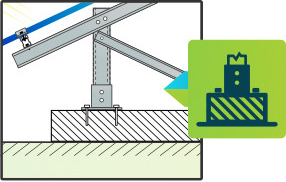

◼ Mechanical anchorage to ballast

The system can be fixed to concrete ballasts according to the specified parameters.

The system can be fixed to concrete ballasts according to the specified parameters.

• profile type: steel „C” profile

• profile length: individually determined based on the installation plans

• fixing method: 2 pcs. of M12 chemically anchored threaded rods/leg in lengths chosen according to concrete ballast size

• size of concrete ballast: individually determined based on structural plans

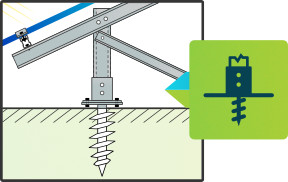

◼ Anchoring with ground screw

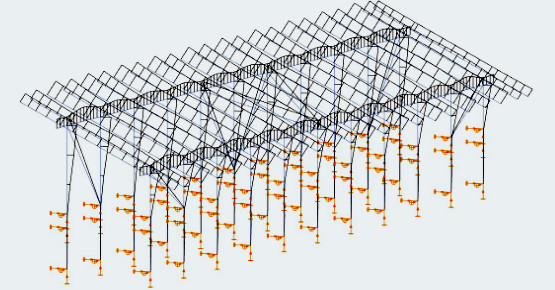

HI-TECH ENGINEERING SOLUTION

Our experts carry out the design, numerical modelling and physical testing of components and complete systems for mounting solar panels.

We offer customized solutions tailored to our customers’ needs.

For structural optimizations a case study is made with:

- Calculations based on Eurocodes

- Extraction tests and optimization of connections

- Soil characterization

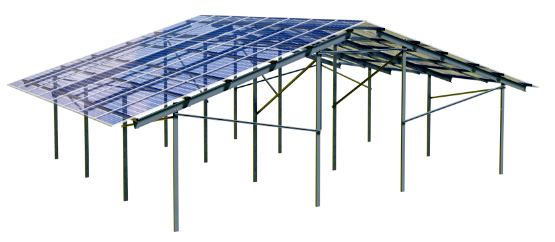

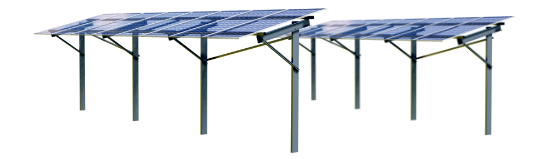

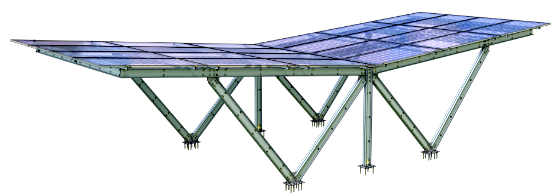

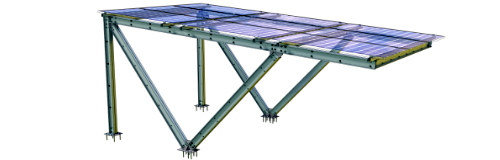

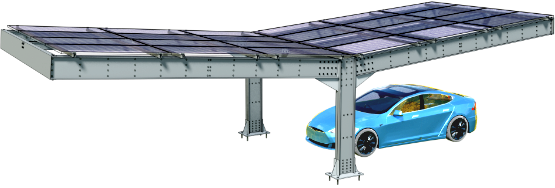

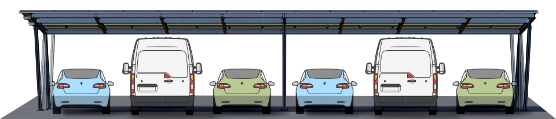

CUSTOMIZABLE SOLAR CARPORT STRUCTURES, PARKING SPACES

Increasing electricity consumption and the need to reduce CO2 emissions are the main reasons why car parks equipped with photovoltaic panels are increasingly favored in cities that want to be as green as possible.

The use of steel to build the supporting structures for these solar carports makes it even more environmentally friendly, as steel is a durable and 100% recyclable material.

The structural elements used are cold-formed, corrosion-resistant profiles, so these carport structures do not require any additional surface treatment. The structures are designed by professional engineers, ensuring a durable and efficient system.

ADVANTAGES OF THESE STRUCTURAL SYSTEMS

Easy installation thanks to the detailed plans developed by our designers.

The structural elements are assembled with metric screws, and for each structure the fixing accessories for the photovoltaic panels are also supplied.

MEXI Steel supports its Customers with its own engineers, who are able to prepare for each project the necessary plans and the structural strength calculations for the official approvals.

The structures we manufacture are assembled from cold-formed, corrosion-resistant zinc-coated profiles, so no painting is required.

All manufacturing operations are carried out in-house, minimizing supplier costs and enabling us to offer a more competitive price compared to the classic alternatives available on the construction market.

Time is essential for our customers, which is why lightweight metal structures are the ideal choice.

MEXI® structures comply with the regulations and requirements of EN 1993 – Eurocode 3: Design of steel structures.

IMPLEMENTED PROJECTS

CONTACT US

T: +40 770 105 793 / +40 771 200 142 | E: office@mexisteel.com

EN

EN DE

DE FR

FR IT

IT ES

ES HU

HU